Plastic shot Molding is a process which is utilized to make a series of plastic products. Companies that concentrate on manufacturing plastic using this process have the ability to mass produce a variety of plastic products that are designed to your specs. This write-up has a look at the plastic shot Molding and also layout procedure, as well as it gives some information on just how you could find a plastic injection specialist in your location. Homepage

Mould as well as Product Style

Lots of firms that specialize in making plastic items will likewise have an in home design group. The layout team will certainly have the expertise as well as understanding to work on nearly any kind of sort of style task, despite just how intricate it could be.

Plastic mold designers will certainly usually deal with illustrations making use of CAD software, or they could provide hands-on illustrations if it is suitable to your circumstances. They may additionally have the ability to supply a rapid prototyping solution. After the product has actually been made the group will then exercise the most effective and also most economical method to make your plastic items. This consists of exercising the most effective way to make the molds that are needed for your project. An excellent plastic Molding injection team will certainly be able to deal with a selection of orders, regardless of just how large or small they might be. For the most parts, bulk orders will certainly lower the specific price of each plastic product.

Plastic Injection Molding

The plastic shot process will certainly vary relying on the firm that you prefer to deal with. The majority of commonly it will include melting plastic pellets until they become soft sufficient to be infused right into a mould of your choice. The plastic will certainly then solidify in the mould, so that the form of the mould is duplicated down to the smallest detail. After the plastic has actually completely cooled and also established the mould is opened up to expose the plastic product. The plastic injection Molding procedure commonly consists of clamping, shot of the dissolved plastics, house, cooling, opening of the moulds as well as ejection to launch the completed product. A plastic injection specialist will certainly be able to encourage you in more information regarding what the whole process involves.

Quality assurance

A plastic shot Molding maker will certainly have a number of systems in position to ensure that the high quality of the items continue to be high and also constant. Quality control specifications will certainly be designed and also composed for every private product set depending upon your requirements.

Ways to Discover a Plastic Shot Mold Professional

The best place to look for a company that is experts being used plastic mold shot systems is online. All major business will certainly have an internet site which will certainly enable you to see information on all the products and services that they presently provide. The website will certainly additionally list their contact details as well as info on how you can place an order. Constantly prefer to work with a respectable and also well established company to guarantee that you will certainly be obtaining a terrific service and plastic items which are manufactured to the best quality. Click here

If the mold needs to be adjusted, it's much easier to tweak the style making use of CAD software program compared to it is to forge a completely new mold and mildew using older techniques. More economical dangers are also conducive to better imaginative liberty. As soon as the prototype is authorized, an appropriate longer-lasting mold can be confidently developed for automation.

While some analysts saw the death of the shot molding industry in the surge of 3D printing, others really saw the way that both methods can be utilized with each other for a total advantage. While 3D printing is bound to have a lucrative future, specifically as the fairly new innovation continuously boost, injection molding is still securely at the center of the world's huge plastic manufacturing enterprises and also doesn't appear to be giving up the throne anytime quickly. Rather than checking out the 3D printer as a challenger, it may be a much more beneficial technique for both industries to see how each boosts the other.

Plastic Molding is a procedure that assists produce a vast array of plastic items wholesale. Industries as well as factories that produce plastic products can take advantage of the plastic Molding procedure.

Thursday, May 24, 2018

6 Tips for Making Use Of Fast Prototyping

Quick prototyping can be specified as a modeling method which improves and also speeds up the development of new products. It is a procedure that uses computer aided tools as well as techniques such as 3D printing as well as stereo lithography to produce physical product versions for production tooling and also evaluation. The process can be very practical to item designers, part vendors or even makers and also has a variety of benefits to all who decide to utilize the method.

Rapid prototyping gets rid of constantly that is required to produce patterns, unique tools and mold and mildews for conventional modeling. There is a significant time reduction in between the initial developing as well as the analysis and this speeds up the manufacturing procedure. The exact version is made swiftly offered for function, use, performance and kind screening making use of the method something that would certainly have taken a very long time to achieve making use of the traditional technique. This is because the procedure is greatly automated and developers can also customize items quicker as well as before mass production. You could currently obtain your items out there quick and ahead of your rivals.

Another significant advantage of the prototyping is that designers have the liberty to create designs that are complex in surface areas and also shaped without stressing over accurate manufacturing. This is something that would certainly have been impossible or really laborious to attain with conventional prototyping because of restrictions in physical components as well as prototype tooling. Creativity is taken to the next degree by fast prototyping strategy.

1. Manage complexity

In fact, the aim of this method is to examine the influence of various versions on their efficiency. If there are lots of variables, you may want to take care when brushing them in the exact same breadboard. Moreover, if you have some challenging models, you should damage them right into various builds isolating intricate systems. Then you can join them to imitate the real item.

2. Test specifications

The role of quick prototyping is not restricted to finding out whether a suggestion can work or otherwise. As a matter of fact, an excellent breadboard allows you recognize the variables that allows the procedure to function. Just what you have to do is design the system based on the variables that you think can have a terrific impact on the efficiency. And always remember to examination.

3. Opt for rate

In the beginning, it's not a good idea to obtain the best parts Simply choose what is good enough. What you have to do is get the maximum number of off-the-shelf parts. Actually, it's faster, cheaper as well as provides you the liberty to transform the components when required. If possible, you may want to choose products with brief lead-times as well as selection.

4. Vital parts.

When using off-the-shelf components, you will certainly locate custom-made items also. Producing these pieces on your own is also a smart idea. Really, this is the fastest method. You can also modify them as you discover that your preliminary style was not the best one. For these parts, using rapid prototyping methods is not a smart idea. At this phase, you don't have to make personalized injection parts, specifically if rapid prototyping elements get you exactly what you want.

5. Effectiveness

As for quick prototyping goes, nothing is even worse than ignoring something that belongs to your discovering process. If you think that you could require a more powerful component, you ought to take steps to earn it occur. Now, you need to not stress over expense, design or simpleness. You can care for that later on.

6. Prepare yourself to repeat

Adhering to the points provided above, it will be feasible for you to find out and also find that you should change or do away with a few of your job. While doing so, you will certainly experience an unforeseen scenario. So, exactly what is the option? The service will certainly exist if you become iterate and also versatile. Visit here

If you follow these pointers, you will certainly be able to obtain exactly what you desire. Understanding these things in the beginning will help you conserve time and money in the future. Likewise, it will certainly enhance your possibility of success. Ideally, this will aid you obtain success.

Rapid prototyping gets rid of constantly that is required to produce patterns, unique tools and mold and mildews for conventional modeling. There is a significant time reduction in between the initial developing as well as the analysis and this speeds up the manufacturing procedure. The exact version is made swiftly offered for function, use, performance and kind screening making use of the method something that would certainly have taken a very long time to achieve making use of the traditional technique. This is because the procedure is greatly automated and developers can also customize items quicker as well as before mass production. You could currently obtain your items out there quick and ahead of your rivals.

Another significant advantage of the prototyping is that designers have the liberty to create designs that are complex in surface areas and also shaped without stressing over accurate manufacturing. This is something that would certainly have been impossible or really laborious to attain with conventional prototyping because of restrictions in physical components as well as prototype tooling. Creativity is taken to the next degree by fast prototyping strategy.

1. Manage complexity

In fact, the aim of this method is to examine the influence of various versions on their efficiency. If there are lots of variables, you may want to take care when brushing them in the exact same breadboard. Moreover, if you have some challenging models, you should damage them right into various builds isolating intricate systems. Then you can join them to imitate the real item.

2. Test specifications

The role of quick prototyping is not restricted to finding out whether a suggestion can work or otherwise. As a matter of fact, an excellent breadboard allows you recognize the variables that allows the procedure to function. Just what you have to do is design the system based on the variables that you think can have a terrific impact on the efficiency. And always remember to examination.

3. Opt for rate

In the beginning, it's not a good idea to obtain the best parts Simply choose what is good enough. What you have to do is get the maximum number of off-the-shelf parts. Actually, it's faster, cheaper as well as provides you the liberty to transform the components when required. If possible, you may want to choose products with brief lead-times as well as selection.

4. Vital parts.

When using off-the-shelf components, you will certainly locate custom-made items also. Producing these pieces on your own is also a smart idea. Really, this is the fastest method. You can also modify them as you discover that your preliminary style was not the best one. For these parts, using rapid prototyping methods is not a smart idea. At this phase, you don't have to make personalized injection parts, specifically if rapid prototyping elements get you exactly what you want.

5. Effectiveness

As for quick prototyping goes, nothing is even worse than ignoring something that belongs to your discovering process. If you think that you could require a more powerful component, you ought to take steps to earn it occur. Now, you need to not stress over expense, design or simpleness. You can care for that later on.

6. Prepare yourself to repeat

Adhering to the points provided above, it will be feasible for you to find out and also find that you should change or do away with a few of your job. While doing so, you will certainly experience an unforeseen scenario. So, exactly what is the option? The service will certainly exist if you become iterate and also versatile. Visit here

If you follow these pointers, you will certainly be able to obtain exactly what you desire. Understanding these things in the beginning will help you conserve time and money in the future. Likewise, it will certainly enhance your possibility of success. Ideally, this will aid you obtain success.

Plastic Injection Molding Services And Products

|

Plastic shot Molding is a process which is utilized to manufacture a series of plastic items. Companies that focus on manufacturing plastic utilizing this process are able to mass make a range of plastic items that are created to your specifications. This post takes a look at the plastic injection Molding as well as design process, and also it supplies some information on exactly how you can discover a plastic shot specialist in your area. Homepage

Mould and also Product Design

Several business that specialize in making plastic products will also have an in house style team. The style group will certainly have the experience as well as understanding to work on virtually any kind of type of layout task, regardless of exactly how complicated it may be.

Plastic mould designers will certainly frequently work with illustrations making use of CAD software program, or they can provide manual drawings if it is suitable to your circumstances. They could likewise be able to offer a fast prototyping solution. After the item has been made the group will then work out the best and also most budget-friendly way to make your plastic products. This includes exercising the most effective method to produce the moulds that are required for your task. A great plastic Molding shot team will certainly have the ability to deal with a selection of orders, regardless of just how huge or small they may be. Most of the times, bulk orders will decrease the individual price of each plastic product.

Plastic Shot Molding

The plastic injection procedure will certainly vary relying on the business that you decide to deal with. A lot of commonly it will entail melting plastic pellets till they become soft sufficient to be infused into a mould of your option. The plastic will certainly then set in the mould, to ensure that the form of the mould is replicated to the tiniest detail. After the plastic has actually absolutely cooled as well as established the mould is opened to expose the plastic item. The plastic shot Molding procedure normally consists of clamping, injection of the dissolved plastics, home, air conditioning, opening of the moulds as well as ejection to launch the finalized product. A plastic shot specialist will have the ability to recommend you in even more detail concerning exactly what the entire process entails.

Quality assurance

A plastic shot Molding maker will certainly have a variety of systems in place to ensure that the top quality of the items remain high as well as constant. Quality assurance specs will certainly be made as well as composed for each specific item batch depending upon your needs.

The best ways to Find a Plastic Injection Mold Specialist

The most effective location to look for a business that is experts in using plastic mould shot systems is online. All significant firms will have a web site which will certainly permit you to see info on all of the products and services that they currently offer. The website will additionally note their contact information and information on how you can put an order. Always decide to deal with a credible and also well established business to make certain that you will be obtaining a wonderful solution as well as plastic products which are produced to the highest quality.

If the mold has to be readjusted, it's much easier to fine-tune the layout using CAD software program than it is to create an entirely new mold and mildew making use of older techniques. Less expensive risks are likewise conducive to greater imaginative liberty. When the prototype is approved, a proper longer-lasting mold and mildew can be confidently produced for mass production.

While some analysts saw the death of the injection molding sector in the increase of 3D printing, others actually discovered the manner in which both techniques could be used with each other for a total advantage. While 3D printing is bound to have a profitable future, particularly as the fairly new innovation continuouslies boost, injection molding is still strongly at the center of the globe's substantial plastic manufacturing enterprises as well as doesn't seem giving up the throne anytime quickly. As opposed to watching the 3D printer as an opposition, it could be an extra advantageous strategy for both markets to see how each enhances the other.

Plastic Molding is a process that assists produce a variety of plastic products wholesale. Industries and manufacturing facilities that produce plastic products could gain from the plastic Molding process.

Sunday, May 20, 2018

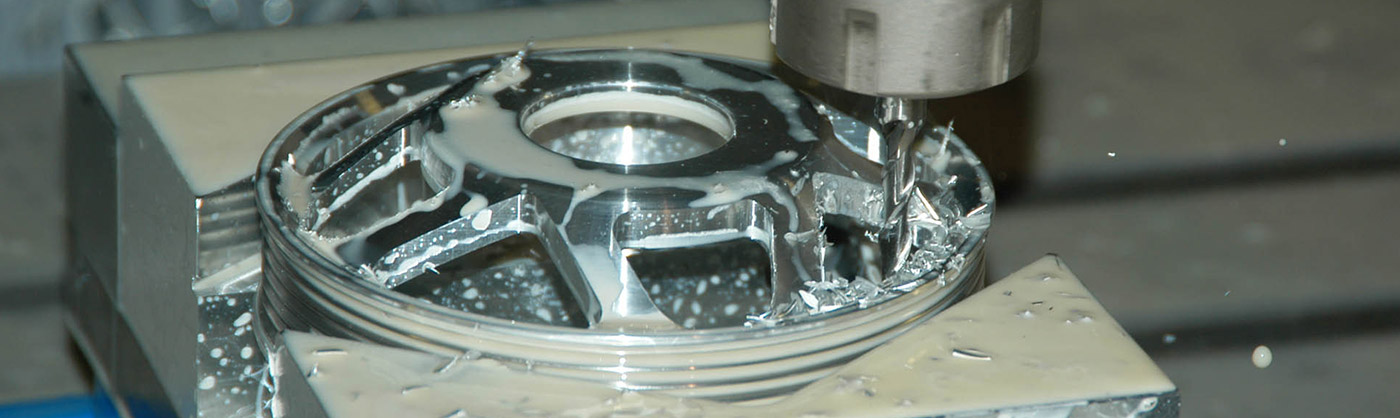

BRIEF HISTORY OF CNC MACHINING

Before CNC machining was invented, all metalworking fabrication processes were completed with NC (Numerical Controlled) machines. The concept of was introduced in 1967 but the first CNC machines were introduced in 1976. Since then the popularity of CNC grew very significant and it was recognized as the industry standard in 1989. Today, we will tell you the brief history of CNC machining.

In 1948, representatives of the US Air Force (USAF) visited the Parsons Corp. headquarters and Parsons was awarded a contract to make new and innovative wing designs for military applications. This, in turn, led to a series of USAF research projects at the Massachusetts Institute of Technology (MIT) Servomechanisms Laboratory, culminating in the construction of the very first numerically-controlled, albeit awkward, machine prototype. To accomplish this, Parsons purchased a Cincinnati DK Series, 28-inch Hydro-tel verticle-spindle contour milling machine consisting of a table and spindle that moved along X, Y and Z-axes. Over the next two years, the Cincinnati was disassembled, significantly modified, retrofitted, and reassembled. As application studies proceeded, the prototype was augmented to produce a motion of the head, table, or cross-slide to within 0.0005″ for each electrical impulse fed by the director. To ensure the prototype was functioning as instructed, a feedback system was added. In response to movement, synchronous motors geared to each motion produced voltage. This voltage was sent back to the detector for comparison to the original command voltage.

By 1953, enough data had been culled to suggest practical, aeronautic applications, and the Cincinnati prototype, which employed a Friden Flexowriter with its 8-column paper tape, tape reader, and vacuum-tube control system, became the de facto prototype for all successive developments. To this day all CNC controlled machines, even the most sophisticated still require three basic systems to operate: a command function system, a drive/motion system, and a feedback system.

Although CNC gained slow acceptance throughout the ’50s, in 1958 MIT Servomechanisms Laboratory developed g-code, which has become the most universally used operating language for CNC devices.

In the early ’60’s the Electronic Industry Alliance (EIA) standardized g-code and computer-aided design (CAD) became a nascent technology providing a firmer technology foundation. As a result, CNC soared and began steadily supplanting older technologies.

By the ’70s, minicomputers such as the DEC PDP-8 and the Data General Nova made CNC machines more powerful and cost-effective. US companies responsible for the CNC revolution, focused on high-end equipment. German and Japanese companies sensing the need, began producing smaller, less expensive CNCs, and since 1979 they have been outselling the United States.

Finally, PCs have now made CNC controls even cheaper, making way for the use CNC-controlled machines for the hobby and general purpose markets. CNC control language now known as LinuxCNC (formerly known as Enhanced Machine Controller, or EMC2) continues to thrive, as are many other CNC technologies.

JasonMould is one of the best plastic injection molding makers that offer great services to their clients when it comes to manufacturing advanced molding tools. They export their tools to different parts of the world and have become one of the most famous names in the industrial sector.

Inquiry Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: info@jasonmolding.com

Website: https://www.jasonmolding.com

Article Original From:https://www.jasonmolding.com/brief-history-of-cnc-machining/

UNDERSTANDING WITH THE INJECTION MOLDING PROCESS

With the use of injection molding presses and high-performance resins, plastic injection molders are able to craft a broad range of quality custom parts. Just as all resins are unique, these sophisticated machines offer varied capabilities and performance options depending on press size and type.

To ensure optimal quality and value, it’s critical to partner with a manufacturer who can provide the right size press for your specific needs.

How Are Plastic Injection Molding Presses Rated?

An experienced plastic injection molder can help you select the correctly sized machine for your project, and will be able to provide you with an accurate size estimate right from the start based on a few key pieces of information.

Presses are rated, or classified, based on tonnage, which indicates how much clamping pressure a particular machine can offer. Press tonnage, or force, can range from less than 5 tons to over 4,000 tons. The higher a machines tonnage is rated, the larger it is.

Many plastic injection molders provide a list of molding equipment used in their facilities on their websites, along with each machines’ tonnage capabilities.

How Much Clamping Force Do I Need?

Pressure keeps a mold closed during the injection process; too much or too little can compromise quality and result in flashing — the appearance of excess material on the part edge. To determine the appropriate size press for your application, consider the following key variables:

- Press rating— A machine with a 68-ton rating, for instance, will be able to deliver 68 tons of clamping pressure, or force.

- Material choice and MFI— The melt flow index (MFI) of plastic, or melt flow rate (MFR), indicates the ease of flow of a molten plastic material. A high MFI will require more pressure than a low MFI.

- Size— The size of the part will naturally affect the size of the machine needed. Many calculations include platen size in addition to mold and part size.

- Safety factor— A numerical percentage incorporated into size calculations to help avoid defects in the final part, the safety factor acts as a buffer; some experts recommend adding 10% to the overall press size estimate.

For most projects, we recommend calculating required machine size using 2.5 times the surface square inches of the part and incorporating the 10% safety factor. So for example, a part with 42 square inches would need a press size with 105 tons of pressure. If you add 10% for a safety factor, you will need to use a press with a minimum of 115 tons of clamping force. A press size of 120 tons would be able to accommodate this plastic injection molded product.

Partnering With a Plastic Injection Molder

Once you have an accurate press size estimate, you can start looking for a manufacturer; generally, molders with a variety of press sizes at their disposal will be able to accommodate a wider range of project requirements. And if your project doesn’t have a completed mold from the start, it’s best to work with a company that excels at injection molding design and building a mold based on exact specifications; this will help ensure efficient, seamless operations and secure communication among all external and internal team members.

At The Rodon Group, our 125,000-square-foot manufacturing plant is home to 117 state-of-the-art injection molding presses, all highly automated, fully robotic, and microprocessor-controlled for industry-leading quality and precision.

To learn more about the plastic injection molding process, download our free eBook, “An Introduction to Plastic Injection Molding.”

About JasonMould Industrial Company Limited

Jasonmould is a manufacturer of plastic molds- injection mold, die casting moulds, plastic blow molding, rotational molding, medical plastic injection molding, two shot plastic injection molding, insert molding, overmolding, metal injection molding, micro injection molding, powder injection molding, ceramic injection molding, liquid injection molding, husky injection molding, household mold, casting mold, die mold tool, custom molds, china moulds, rapid prototyping tooling, plastic prototyping tooling, punch press tooling, die and tooling for mobile/ cell phone parts, automotive parts, vacuum cleaners, rechargeable tools, telephones, copiers, computers, multimedia speakers, and many other electronic products and household appliances. And also a plastic product manufacturer- plastic parts, plastic water tank, plastic balls, plastic containers, plastic buckle, plastic anchor, plastic hanger, plastic spoon, plastic pipe fitting, plastic tumble, plastic tableware, plastic cups, plastic bottles, plastic tray, plastic cosmetic container, plastic case, plastic food container, plastic chairs, plastic caps, plastic cap closure, plastic tubes, plastic water pipes, plastic knobs, plastic tubing, plastic utility boxes, plastic racks and so on.

For more about custom manufacturer of plastic molding products,please visit https://www.jasonmolding.com/

Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: info@jasonmolding.com

Website: https://www.jasonmolding.com

Article Original From:https://www.jasonmolding.com/understanding-with-the-injection-molding-process/

Subscribe to:

Comments (Atom)